The Definitive Guide to What materials do you use for prototype building? - 3D Prints

6 Easy Facts About The Information Needed to Build Your Prototype Described

Wire EDM or Electrical Discharge Machining, is extremely comparable to a CNC Milling because it can cut extremely detailed shapes due to its +/-. 0001 high accuracy capacity. However, the electrically charged brass wire that the EDM machine uses never ever actually touches the surface that it is cutting. This brass (often copper) wire is a tight thin wire, normally.

30m, which can be pictured as a miniaturized conductive floss stick. This Author come from the intrinsic heats that emerge from the high voltage 1000 A arks between the brass wire and object cut. A CNC servo system manages the distance in between the cathode brass wire and anode cutting product.

Steel prototype building demonstrates sustainable approach – newsteelconstruction.com

Getting My Design, fabrication and testing of a prototype, thin-vaulted To Work

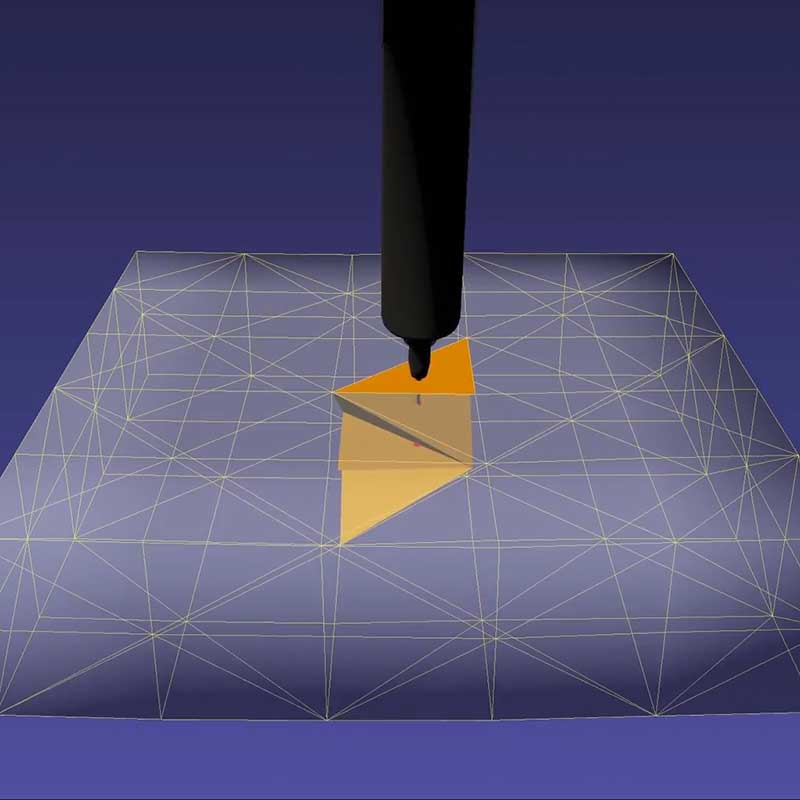

To produce extremely accurate styles, makers utilize kerosine as their dielectric fluid option. Maker, Bot Thing-o-Matic Tabletop Circuit Engraver. Image courtesy of Tomorrow Lab. In 2014 as part of in internal job, we repurposed a Maker, Bot Thing-o-Matic into a circuit engraver to try to make fast PCBs in home.

A fascinating look at living building materials - Soft Tech

In an effort to update, we bought an Other Mill in 2015 to make same-day PCBs for our more quick 48 week Phase No project scopes. It works pretty well, and cuts boards rapidly, though since we normally utilize off the shelf components while prototyping in the early phases, we have not had a chance to utilize its complete potential.

Rethinking the Prototype - Farmworker Housing Design

The Best Guide To Using The Bill of Materials For Prototype Development

Time to check out: 3 min3D printing is a wonderful option for constructing quickly, low-cost prototypes. Small enclosures? Breeze. 5 variations of a door handle? No problem. But what takes place when your measurements surpass that of a 3D printer build bed? Here are a few alternative techniques for building prototypes larger than 1-2 ft.

2-Dimensional Cutters, CNC routing, water jet, plasma cutting or laser cutting are all great choices for developing big prototypes. These processes are mostly 2D in nature, but can provide a greater level of automation for developing numerous models and prototypes with more detailed geometries. You can likewise pick from a big assortment of materials, consisting of metals, plastics, and wood.